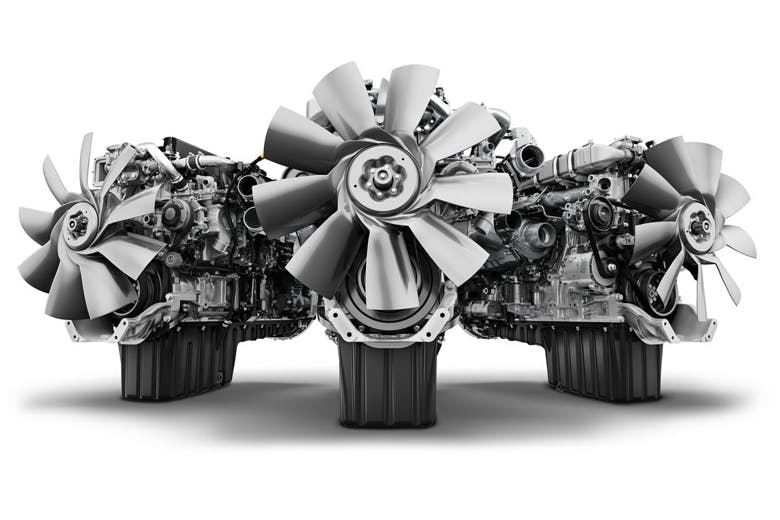

How Detroit Makes the Best Semi-Truck Engine

Freightliner Trucks Parts

Semi-truck engines have greatly evolved over the years, changing the landscape of transportation for the better. Long gone are the days of hand cranking and simple automatic starts; today’s semi-truck engines offer the most advanced green technology and mile marker performances that surpass previous models.

Some of the best semi-truck engine options include Detroit® Engines available across a wide range of Freightliner models. Next-generation engineers have designed advanced engine infrastructure that provides up to 600 horsepower and 2050 pound-feet of torque, allowing for the most challenging hauling, mixing, pulling and dumping applications. Aside from the Detroit’s heavyweight status, their engines represents sought after features not found under other truck hoods. From electronic engine control to turbo compounding, the Detroit is built to boost uptime, improve safety and maximize operation investment distribution. As regulations continue to occur, rest assured that all new Detroit engines are compliant with 2014 Greenhouse Gas (GHG14) requirements.

Top 6 Detroit Engine Features

Maintenance: Simplified

Detroit engines are both built to last and built to be easily maintained. A cartridge-style filter design enables convenient troubleshooting, fast filter locating ability and simple replaceability. Built-in notification settings continually monitor filter levels, informing drivers when any filter’s load is nearing a change need. Detroit engines can go up to 50,000 miles between oil drain, oil filter and fuel filter changes, the longest scheduled maintenance interval in its class.

Lowered Fuel Consumption

Supply truck drivers with the exact amount of fuel they need every moment. Electronic engine controls and Amplified Common Rail Systems (ACRSTM) work in conjunction to refine combustion events while intelligently designed cooling hardware reduces fan on-time operation. As a result, it uses less fuel without sacrificing power due to the compounding effect. Additional Detroit semi-truck engine hardware lends a hand in ensuring quality fuel consumption, including:

- An optimized fuel pump

- A modified fuel injector nozzle

- An optional variable speed water pump

- Helps to reduce engine loads by analyzing coolant temperatures, driving speed and controlling overall flow

- A friction-optimized piston design

Better Emissions Efficiency

The best semi-truck engines are able to decrease exhaust emissions without sacrificing the power needed to merge on the highway, change lanes and pass traffic. And the Detroit engine family is no exception. BlueTec® SCR emissions technology is engineered for Detroit engines so business can remain productive while truck operation yields less fuel burning. The Detroit semi-truck engine series meets current government standards, including compliance with the GHG14 (Greenhouse Gas) and 2013 OBD (OBD13) regulations.

Jacobs® Braking Technology

Integrated braking advancements are a standard for Detroit semi-truck engines. Boasting three levels of braking capabilities, this braking system delivers safer, quieter braking power. Drivers can turn on their Jacobs® Engine Brake while in transit for a more peaceful stop while traveling late at night or for more controlled stopping power in downhill areas.

Turbo Compounding

Less fuel, same amount of horsepower. That’s the potential of turbo compounding. By working alongside Freightliner’s exclusive ACRS fuel system and BlueTec emissions technology, these semi-truck engines are able to utilize a exhaust stream’s otherwise wasted energy. Rather than excess exhaust exiting the truck’s system, the Detroit’s turbo compounding solution converts the thermal energy into power, simultaneously saving time and money on fuel-up stops and reducing overall waste.

Virtual Technician

Factory installed Virtual Technician comes standard on all Detroit engines. This onboard diagnostic system takes the guesswork out of engine repair. If the check engine light should come on, the information is sent to you and to Detroit Customer Support Center where a trained representative can diagnose the issue (should I continue driving or should I pull over?), recommend service, and put you in touch with the nearest dealer.