SuperTruck II reflects our relentless pursuit of freight efficiencies to focus on core components that are already critical to real-world savings today and will become more important tomorrow: powertrain, rolling resistance, aerodynamics, and safety. With our customers at the center of all we do, the innovation behind SuperTruck II resulted in technologies that can lead to results sooner rather than later.

The wind creates perfect shapes in nature and now it creates them around SuperTruck II.

Wind tunnels don’t lie. What the eye sees is not always what the air sees—an aerodynamic truck with a sculpted bumper, hood, windshield and mirrors that cuts right through it.

Automatic side extenders and a roof spoiler close the gap between the tractor and trailer down to 4 inches at highway speeds.

Dynamic ride height decreases drag by automatically lowering the truck at highway speeds, with no effort required from the driver.

New rubber, new tread, new technologies, it’s all about minimal friction and maximum efficiency.

Our Michelin partnership created new tire compounds, new treads and new technologies.

At highway speeds, axles automatically shift from 6x4 to 6x2, extending tire life.

At highway speeds, dynamic load shift automatically shifts some of the trailer weight from the drive tire to the tag axle, minimizing the vehicle’s rolling resistance.

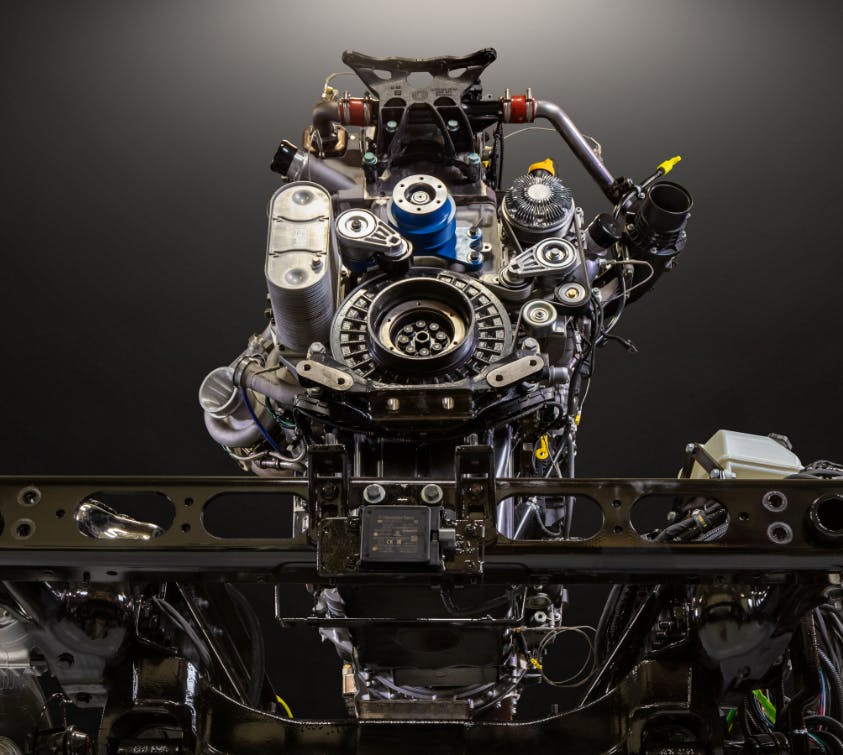

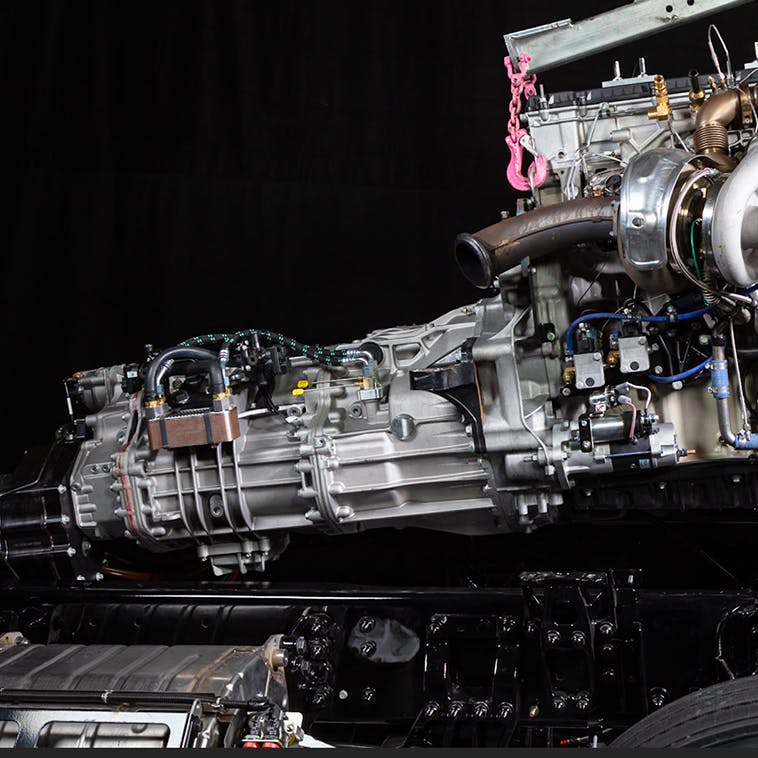

Maximizing powertrain efficiencies now includes turning the powertrain off.

A 13-liter engine with twin turbo and interstage cooling delivers more efficient air compression.

On downhills the engine automatically shuts off. Everything else is battery powered.

An added 13th gear achieves lower down-speeding and higher fuel savings.

We've taken a completely new approach to power and safety.

Fully run the hoteling feature without the engine running using the 48-volt electrical system.

The 48-volt power steering system uses significantly less power by adjusting demand only as needed, whether maneuvering at low speed or driving at highway speeds.

Mirrorless cameras are aerodynamic, out of a driver’s line of sight, and provide better visibility for the driver under low light conditions.

From the design and engineering teams’ efforts, to working with partners, to real-world testing, this truck was a full-on collaborative effort on a global scale.

Inspired by the wind and fine-tuned through clay models and prototyping, our most aerodynamic truck was created. The collaboration between the advanced engineering group, Detroit powertrain engineers, and the global powertrain team was critical to developing an even more efficient engine and transmission—one that met our increasingly higher demands for energy efficiency.

With a truck like this, there’s only one way to build it, and that’s by hand. That’s exactly how we did it, panel by panel, until the last one fell perfectly into place.

We drove this truck over thousands and thousands of real-world miles, in all conditions. We pushed it. We learned from it.

As a heavy-duty truck manufacturer, we create new technologies and designs for a reason—for our customers and their needs. When it comes to our brand, our customers, our industry and our planet, we strive to be relentless. We never stop innovating. That’s the way it’s always been for Freightliner, and that’s the way it will always be.

To view the full press kit, please click here.